Types of Heat Press Machines

Types of Heat Press Machines

There are several types of heat press machines, each designed for different applications, materials, and production needs. Here’s a breakdown of the most common types:

1. Clamshell Heat Press

Best for: Beginners, small businesses, T-shirts, and flat items.

- Design: The upper heating plate folds down like a clamshell.

- Pros:

- Compact and affordable.

- Easy to use (one-handed operation).

- Cons:

- Limited space for thick items (like hoodies with zippers).

- Less even pressure compared to swing-away models.

2. Swing-Away Heat Press

Best for: Professional use, thicker materials (towels, bags, hats).

- Design: The heating plate swings out completely, allowing full access to the lower platen.

- Pros:

- Better pressure distribution.

- Accommodates bulkier items (e.g., padded jackets).

- Cons:

- More expensive than clamshell.

- Takes up more space.

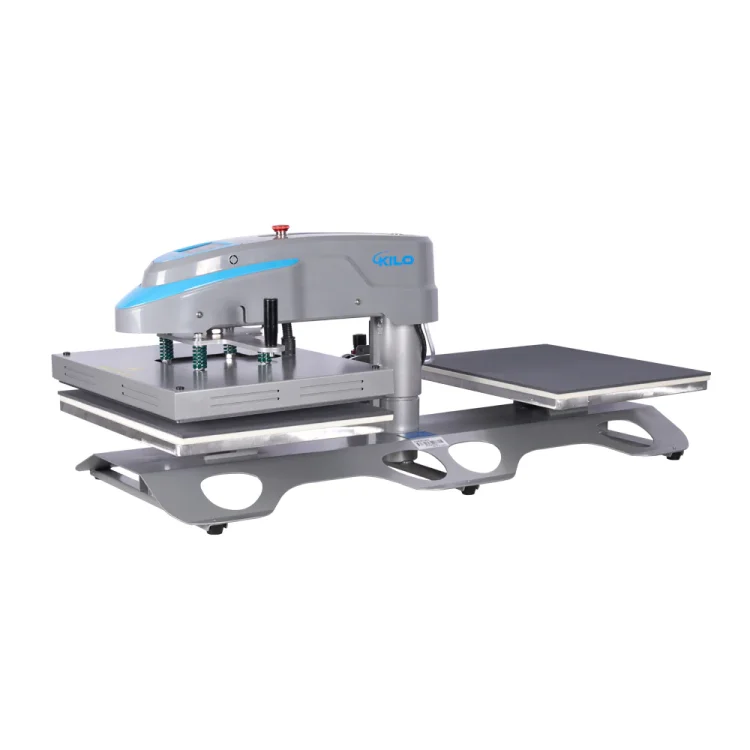

3. Drawer-Style Heat Press

Best for: High-volume production, sublimation on flat items (like mouse pads).

- Design: The lower platen slides out like a drawer for easy placement.

- Pros:

- Great for precise alignment (good for multi-color transfers).

- Consistent pressure.

- Cons:

- Not ideal for thick fabrics.

- Less common than clamshell/swing-away.

4. Multi-Purpose (Hybrid) Heat Press

Best for: Versatility (can press shirts, mugs, caps, plates, etc.).

- Design: Comes with interchangeable attachments:

- Flat platen (for shirts).

- Mug press (for coffee mugs).

- Cap press (for hats).

- Plate press (for ceramics).

- Pros:

- Saves money (one machine does multiple jobs).

- Cons:

- Attachments may not be as efficient as dedicated machines.

5. Automatic (Digital) Heat Press

Best for: Large-scale businesses, consistent results.

- Design: Uses pneumatic pressure and digital controls for precision.

- Pros:

- Fully automated (consistent pressure & timing).

- High efficiency for bulk orders.

- Cons:

- Expensive.

- Requires more maintenance.

6. Manual (Lever-Based) Heat Press

Best for: Budget users, occasional projects.

- Design: Uses a manual lever to apply pressure.

- Pros:

- Cheaper than digital models.

- Cons:

- Less consistent pressure.

- Requires more effort.

7. 3D Vacuum Heat Press

Best for: All-over prints (AOP), sublimation on curved objects.

- Design: Uses a vacuum to wrap heat around 3D items (like shoes, phone cases).

- Pros:

- Great for complex shapes.

- Cons:

- Expensive.

- Limited to sublimation.

Which One Should You Choose?

- Beginners/Hobbyists: Clamshell or swing-away.

- Small Businesses: Swing-away or multi-purpose.

- High-Volume Production: Automatic or drawer-style.

- Sublimation on Mugs/Hats: Multi-purpose or dedicated mug press.

Would you like recommendations based on your specific needs?

.